Years ago I was reversed into …… a HGV stopped on a main A road, we and the traffic behind us stopped as well. Then he reversed. Instinct 1 – horn, instinct 2 – bale out, or be crushed. As accidents go, being reversed into is quite a slow affair, time enough then to process the outcome, time enough to let the dread take hold. My step father and I were lucky, trapped by the car behind with nowhere to go, a quick thinking German jumped the line of traffic and drove alongside the tractor unit with his horn blaring.

Years ago I was reversed into …… a HGV stopped on a main A road, we and the traffic behind us stopped as well. Then he reversed. Instinct 1 – horn, instinct 2 – bale out, or be crushed. As accidents go, being reversed into is quite a slow affair, time enough then to process the outcome, time enough to let the dread take hold. My step father and I were lucky, trapped by the car behind with nowhere to go, a quick thinking German jumped the line of traffic and drove alongside the tractor unit with his horn blaring.

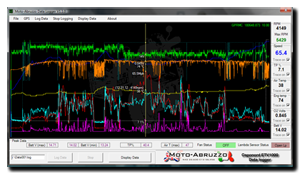

Role on to yesterday ……. heading back home on the heavily laden Capo. I take a right turn onto a decent section of road I know well. Ahead is a HGV. He’s moving at a reasonable speed and I’m in no hurry, so I settle on the crown of the road about 100m behind. In about 2Km I’m turning left (pic. above), about 75% of traffic turns there …. So it’s quite conceivable this chap will as well. In my mind I’m setting up for the overtake once we’ve settled down after the turn.

We approach the junction doing about 70Kmh and his left indicator starts flashing. A second later I indicate as well. He starts braking and I back off the gas. I’m thinking he’ll shave off 20-30Kmh to make the turn. As you can see from the picture above, it’s a wide open junction with good visibility.

Then things rapidly unravel.

I’m still at the crown of the road, so I can see his mirror clearly …. And the fact that he’s scrubbing off way more speed than I’d anticipated – he’s stopping! I’m now about 30m behind.

He stops …. I stop about 15m behind, in clear view of his mirror. He’s still indicating left.

Then it happens. The engine revs, the reversing lights go on and with a lurch he’s accelerating backwards towards me.

It takes 0.7 seconds to process and react so they say.

14m, 12m, 10m ……..my thumb hits the horn button …… and the Stebel Nautilus sings out. It echoes off the back of the truck and floods through my earplugs, it gets the job done. Sleeping Beauty is awoken from his afternoon siesta by the 139db kiss on his delicate eardrums.

And just like that, the situation is defused, my pulse falls as I ride away and I realise my tongue is well and truly stuck to the top of my desert-dry mouth. The weak knees and tremors take a bit longer to fade away.

Why this muppet did what he did I have no idea, the nearest entrance behind us was about 400m and anyway, the junction is so spacious and quiet he could have turned around easily. I guess I’ll never know what thought was crossing that barren wasteland called his brain.

idea, the nearest entrance behind us was about 400m and anyway, the junction is so spacious and quiet he could have turned around easily. I guess I’ll never know what thought was crossing that barren wasteland called his brain.

The question is, would the situation have had the same outcome if I hadn’t recently fitted the Nautilus …..

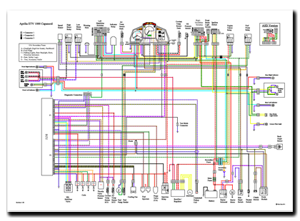

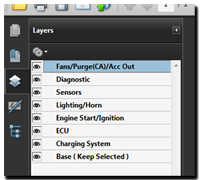

It’s not often these days that something really useful comes along, but Chris Elms has pulled one out of the bag! He recently popped over to the AF1 Caponord forum and quietly dropped off two wiring diagrams. Nothing new you might think – we’ve had wiring diagrams with the workshop manuals for years.

It’s not often these days that something really useful comes along, but Chris Elms has pulled one out of the bag! He recently popped over to the AF1 Caponord forum and quietly dropped off two wiring diagrams. Nothing new you might think – we’ve had wiring diagrams with the workshop manuals for years.

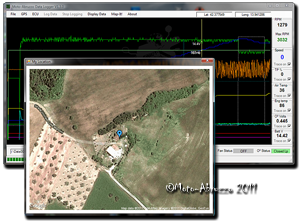

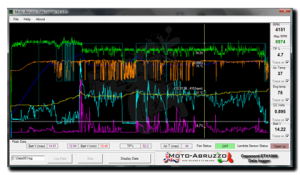

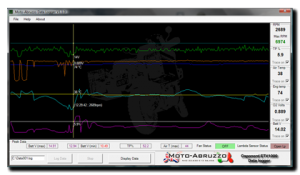

(measured not GPS), brake line pressure and gear position may well be handled by this little device. 8 x 5v analogue inputs should be fine … all looks fairly straight forward in the instruction book anyway. We’ll see!

(measured not GPS), brake line pressure and gear position may well be handled by this little device. 8 x 5v analogue inputs should be fine … all looks fairly straight forward in the instruction book anyway. We’ll see!

The new

The new

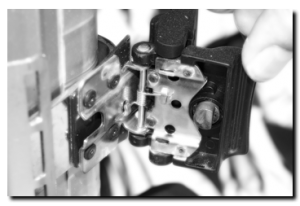

A last item remained on the Capo service ‘To-Do’ list … fork oil replacement, a job I hadn’t tackled before. It turned out to be a nice simple job, the only fly in the proverbial being the Aprilia document itself ….. or to be more exact, the amount of oil specified in the document.

A last item remained on the Capo service ‘To-Do’ list … fork oil replacement, a job I hadn’t tackled before. It turned out to be a nice simple job, the only fly in the proverbial being the Aprilia document itself ….. or to be more exact, the amount of oil specified in the document.