During its life the Capo has had two Lithium batteries – the original Shorai, fitted in October 2011 and used for about 3 months, and now the NOCO NLP14. It’s fair to say, similar technologies, but also a decade of development different.

During its life the Capo has had two Lithium batteries – the original Shorai, fitted in October 2011 and used for about 3 months, and now the NOCO NLP14. It’s fair to say, similar technologies, but also a decade of development different.

So what was the original problem with the Shorai? Very simple answer – temperature. Above an ambient 13-15C it would crank the Capo no problem, but cross below that particular Rubicon and it just stalled the starter motor until some heat was put into the battery, usually by running the headlights for a few minutes. Frankly, this was an absolute pain, hence swapping back to a good-old lead acid battery. It is this particular niggle that I have not come across yet with the NLP14 in my ZZR1200 even though we have had night-time temperatures dipping down to as low as -7C of late.

Installation

The NLP14 comes with some smashing cast/machined brass terminals that look lovely and offer a multitude of connection points – pretty and practical. But also too clever for their own good! On the Capo, Andy (Beasthonda) found that they caused the cables to sit far too close to the frame. So the terminal was modified by cutting approx. 4mm from the two sides and making the fixing hole into a slot to compensate. This allows the terminal to sit further ‘into’ the battery body and clear the Capo cables away from the subframe.

An alternative fix is to buy a couple of brass screw-on terminals from Motobatt. The MB-TERM-003 fitted just perfect and although they don’t look anywhere near as pretty as the NOCO terminals, they do the job just fine without cutting and drilling. They are made of 4mm thick brass and also have two extra attachment points – the upper being standard for the Capo. You can see from the pics, that there is a cover between the terminals held by one screw … this needs to be removed to fit the battery into the Capo. It’s simply ‘bodywork’ and just makes the battery mimic the shape of a few different battery types. In the end the battery took a only a few minutes to replace and is an almost exact fit for the Capo battery box (no padding required!) and the cables are well clear of the frame as well.

Performance

Simple …. It does exactly what it claims on the website. Both the Capo and the ZZR batteries have performed perfectly through winter – neither giving a moments problem. In fact, recently, the ZZR spent an extended time away and after a few weeks the tracker warned of a low battery voltage. Annoying, but to be expected with a tracker and camera system drawing parasitic voltage for such an extended period. By the time I got to it, the voltage was well down for a Lithium battery and I had taken my jump starter pack along as I expected to need it. In the end, even with the voltage reading only 12.18V I was gobsmacked that it fired up when I hit the starter button out of childish curiosity! But of course, the ZZR is a lovely inline-4 …. would the battery still crank the quirky-Capo in the same predicament? Truthfully …….. I don’t think I would have tried, we’ve all heard the camp-fire tales of dashboards going south and other electrical gremlins coming to play when poor-voltage fairy is on hand.

Secondly, I bit the bullet on an

Secondly, I bit the bullet on an

And so the moment came and went without fanfare after a year of lockdown, no trips back and forth to home in Italy, no big holiday rides here in the UK. A year where mileage clocked up painfully slowly, the Capo sitting idle way more than doing what it does best – eat miles and promote smiles!

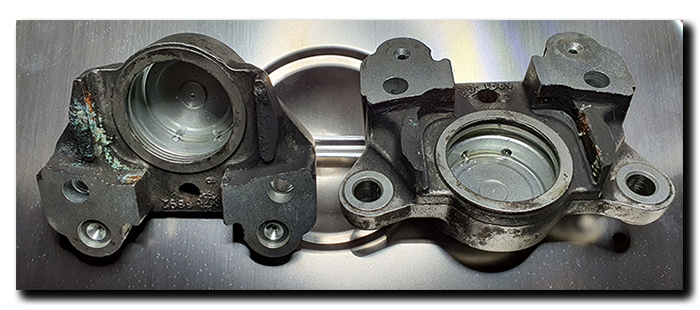

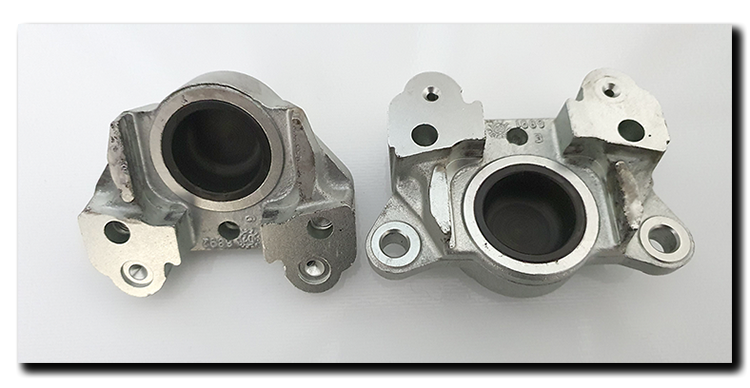

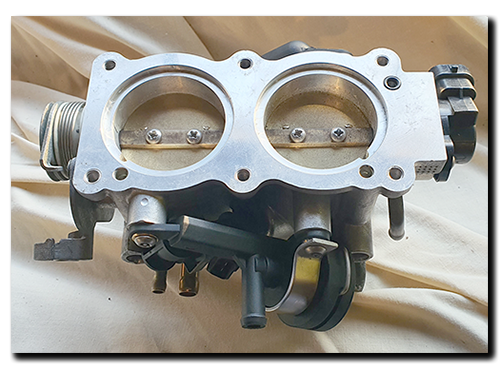

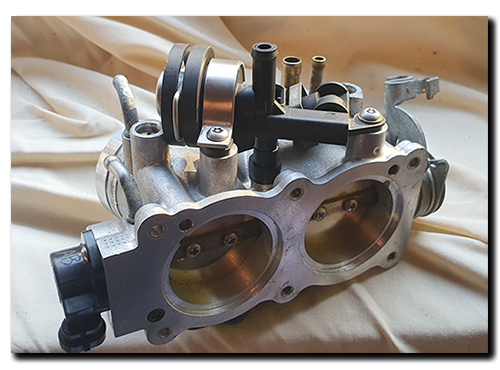

And so the moment came and went without fanfare after a year of lockdown, no trips back and forth to home in Italy, no big holiday rides here in the UK. A year where mileage clocked up painfully slowly, the Capo sitting idle way more than doing what it does best – eat miles and promote smiles! Sometime way-back-when, I bought a used set of throttle bodies off an RTS Futura (51mm v Caponord 47mm) with the view of doing some tuning/comparison work on the Raid with the 3D printed hybrid velocity stacks (51mm diameter but Caponord height). What really happened though was far less glamourous and only involved a sturdy box and a shelf! But about a month ago I dug them out again and realised that I pretty much had all the ingredients required to do a full clean and rebuild. I had stainless steel 4x10mm and 5x12mm Torx screws on the shelf as well as all necessary seals. The ultrasonic cleaning bath would do the brunt of the work and I could send the injectors away for professional cleaning at a reasonable cost.

Sometime way-back-when, I bought a used set of throttle bodies off an RTS Futura (51mm v Caponord 47mm) with the view of doing some tuning/comparison work on the Raid with the 3D printed hybrid velocity stacks (51mm diameter but Caponord height). What really happened though was far less glamourous and only involved a sturdy box and a shelf! But about a month ago I dug them out again and realised that I pretty much had all the ingredients required to do a full clean and rebuild. I had stainless steel 4x10mm and 5x12mm Torx screws on the shelf as well as all necessary seals. The ultrasonic cleaning bath would do the brunt of the work and I could send the injectors away for professional cleaning at a reasonable cost.

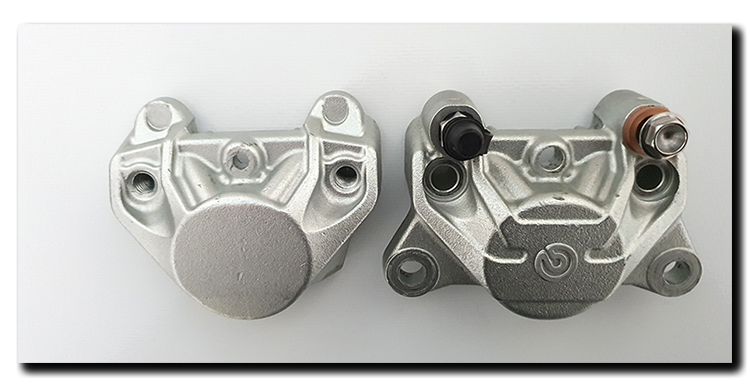

I really like fasteners, I hate rusty, corroded or damaged fasteners. There it is out in the open, plain and simple. I think there’s something tragic about lots of hard work going into an assembly, only for those old jaded screws/nuts/bolts/washers to go back into holding it together. On the other hand I’m not a fan of those OTT ‘custom fasteners’ – pike nuts etc or gaudy anodised fasters in any colour of the rainbow. For me, they are way overkill. What I want is an upgrade from the manufacturers items that were no doubt chosen with cost in mind. I like something that looks a little more up-market, in a material that is mechanically safe for the task in hand – safety has to override looks every time! They are there to do a job and complement the work that went into the parts they represent.

I really like fasteners, I hate rusty, corroded or damaged fasteners. There it is out in the open, plain and simple. I think there’s something tragic about lots of hard work going into an assembly, only for those old jaded screws/nuts/bolts/washers to go back into holding it together. On the other hand I’m not a fan of those OTT ‘custom fasteners’ – pike nuts etc or gaudy anodised fasters in any colour of the rainbow. For me, they are way overkill. What I want is an upgrade from the manufacturers items that were no doubt chosen with cost in mind. I like something that looks a little more up-market, in a material that is mechanically safe for the task in hand – safety has to override looks every time! They are there to do a job and complement the work that went into the parts they represent.

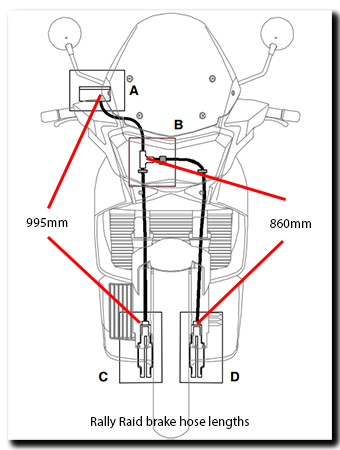

Well this little job just got a whole lot more involved and costly! The idea of having lovely clean and refreshed calipers made me think about the old banjo bolts (M10x1) and bleed screws (M8x1.25) … OK, so new stainless ones were ordered from

Well this little job just got a whole lot more involved and costly! The idea of having lovely clean and refreshed calipers made me think about the old banjo bolts (M10x1) and bleed screws (M8x1.25) … OK, so new stainless ones were ordered from  The standard hose assembly is a single hose from the reservoir to a T-piece just below the lower fork clamp, from there a single hose down to each caliper. To replicate this was actually more expensive than using two individual lines from the brake master cylinder. So that’s what I went with –

The standard hose assembly is a single hose from the reservoir to a T-piece just below the lower fork clamp, from there a single hose down to each caliper. To replicate this was actually more expensive than using two individual lines from the brake master cylinder. So that’s what I went with –