Today a post on a new bit of kit in my wardrobe and how a couple of companies renew your faith in how retail should work.

Today a post on a new bit of kit in my wardrobe and how a couple of companies renew your faith in how retail should work.

First, the bit of kit …. a black Helite e-Turtle2 air vest with optional motorcycle sensor kit. In all honesty I’ve been dancing around the purchase of one of these safety garments for a couple of years, but only just bit the bullet after a rather sobering article in the press, where a Police rider heaps praise on one of these devices that saved him from serious injury after a rather ugly incident on the M25. Later I learned that 16 Police forces now use these devices along with many other agencies. I was sold, and the order was placed with sportsbikeshop.co.uk for the vest, sensor kit and a spare gas canister. Of course I don’t ever really want to use the first canister, let alone a second, but as the saying goes …. better to have one and not need it, than need it and not have one!

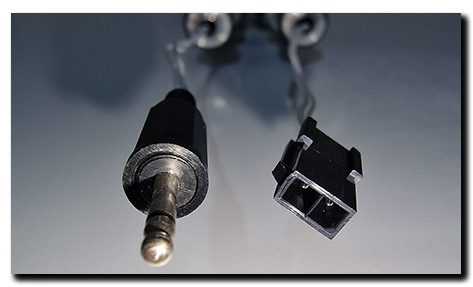

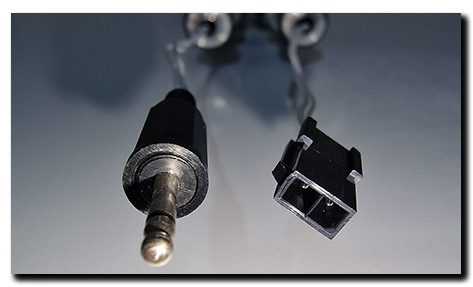

Within a couple of days I was stood marvelling at my new purchase, more on which I’ll write later. But before that, I have to tell you the ‘good retail’ story! Being a curious sort of soul, I opened the spare canister and compared it to the canister fitted in the vest …. there was a difference. The electrical connector in the vest was a locking two-pin item, but on the spare canister it was a jack plug. Hmm … had I ordered the wrong one? Back to sportsbikeshop …. no, they only listed the one type of 100g canister. OK, over to the Helite website and slap me sideways, only the same canister with the jack plug is shown. Now I

Within a couple of days I was stood marvelling at my new purchase, more on which I’ll write later. But before that, I have to tell you the ‘good retail’ story! Being a curious sort of soul, I opened the spare canister and compared it to the canister fitted in the vest …. there was a difference. The electrical connector in the vest was a locking two-pin item, but on the spare canister it was a jack plug. Hmm … had I ordered the wrong one? Back to sportsbikeshop …. no, they only listed the one type of 100g canister. OK, over to the Helite website and slap me sideways, only the same canister with the jack plug is shown. Now I  was stumped. So the next day I called Helite and received a massive apology as it turned out the new vests (Mk2?) have the locking plug connector and a batch of spare canisters had only just been received, so no distributors had them yet! Now this could turn ugly … Helite could say get your distributor to sort it out and the distributor could argue they sold me what Helite say fits. But not in this case – both were fantastic, Helite sent Sportsbikeshop a batch of canisters and explained the issue, meanwhile Sportsbikeshop and I swapped a couple of emails and hey-presto a correct canister arrived this morning, just 48hrs after noticing the problem … no fuss, no arguing, just good old fashioned customer support – so thank you both, I’ll be buying from you again that’s for sure!

was stumped. So the next day I called Helite and received a massive apology as it turned out the new vests (Mk2?) have the locking plug connector and a batch of spare canisters had only just been received, so no distributors had them yet! Now this could turn ugly … Helite could say get your distributor to sort it out and the distributor could argue they sold me what Helite say fits. But not in this case – both were fantastic, Helite sent Sportsbikeshop a batch of canisters and explained the issue, meanwhile Sportsbikeshop and I swapped a couple of emails and hey-presto a correct canister arrived this morning, just 48hrs after noticing the problem … no fuss, no arguing, just good old fashioned customer support – so thank you both, I’ll be buying from you again that’s for sure!

So with that little drama behind me and the rain cloud parting it was time to delve into the fascinating world of air vests. The setup of the vest is simple – pop it on charge with the supplied cable and when the vest LED changes from amber to green, you are good to go. Battery life is rated at up to 25hrs with the led turning amber when the vest has approx. 2hrs of life left. Charging takes approx. 5 – 7 hrs so they say. The charging cable supplied is a USB to power plug – an unusual cable and not one you’re likely to have kicking around, so I figure it should stay with the vest for safe keeping … and there is a tiny pocket in the vest that’s not much use for anything more than a credit card or loose change but is ideal for storing the cable – sorted.

Next up then, the motorcycle sensor. First you need to pair this to the vest (dead easy) then fit it to the fork leg of your bike. Again, very easy with various length straps and bits to fit a massive range of fork diameters. They say the sensor is good for up to 5 years and should be tested monthly using a little magnet supplied. Now my bike looks like a local bad boy wearing a tag on his ankle! Incidentally, the vest can be paired with up to 5 sensors if you have multiple bikes. Nice.

Now the air vest itself. Well the construction is first class and I would say the fit … unobtrusive and comfortable. I bought the XL-L, one for the more ‘portly’ rider …. both the XL and XL-L use a 100g canister while the smaller size vests us a 60g canister as their air bag volume is smaller. This does add a little more weight to the right-hand side of the vest, but once you’re wearing it the weight disappears. In use the vest is absolutely fine and doesn’t hinder my movement at all, you can even wear a rucksack with it, but there are a few caveats (loosen straps etc) otherwise you could be in a right pickle if it deploys! Turning the vest off and on is a simple quick-three-taps of the button. If the vest is powered up, but doesn’t move after 40 seconds, it goes to sleep to conserve power. To wake it up, simply move the vest and you’re good to go again. The vest itself comes with a 2 year warranty which extends to 4 if you register it with Helite. They do recommend the vests are returned yearly or at most two yearly, if damaged or deployed more than 7 times for a service/inspection, which appears to cost approx. £75 plus p&p.

So far so good. Putting aside what the vests purpose is for a moment (loads of YouTube videos available anyway) I just want to spend a moment thinking about some of the features which I think should or could be addressed in a Mk3 version to make the garment even better. In my eyes, they’ve missed a trick by not pairing the vest with an app. I know, everything nowadays has an app … but when well written they enhance the function of a device and I think the Turtle vest could greatly benefit from one. Take power for instance, the vest only uses LED/beeper to inform battery status – an app could show detailed info and predict when the vest will run out as well as being used to alert the rider. An app could also show electronics pack and motorcycle sensor status and again, be used to alert the rider if either develops a fault. An app could also for example, be used to alert emergency services when a deployment is registered. And what about selective profiles road/race/off-road algorithms (like ECU maps) and the ability to detach from the motorcycle sensor if required. I’m sure there are many other things as well, but that’s just a few that come to mind.

Also on the wish list – charging. The current 5 – 7 hours seems a long time, I’d like to see fast-charge functionality bring that down to 2 -3 hours if possible. Also the charging cable .. why a proprietary power connector when USB-C is now becoming the connector of choice? And while you’re at it, design the electronics it to accept charge while it’s functioning (currently it only does one or the other) then a power pack can be connected for those looooong days in the saddle! After all this, please don’t think I’m maligning the existing e-Turtle2 vest, I’m not, and I’m really glad I purchased it. I’m just thinking how a great product could be made better and even more user friendly in the future.

Lastly I just want to mention the differences (as I see them) between the standard Turtle2-lanyard deployed and the e-Turtle2. In essence the only difference appears to be the triggering method – one electronic and one that uses a lanyard attached to the bike. The latter requires the rider to move far enough away from the bike for the lanyard to separate from the vest, thus triggering the air bag deployment. The electronic vest relies on sensors and magical algorithms to do the same (and the bikes sensor if fitted) … bottom line, deployment should be quicker and reliable for different incident situations.

Today a post on a new bit of kit in my wardrobe and how a couple of companies renew your faith in how retail should work.

Today a post on a new bit of kit in my wardrobe and how a couple of companies renew your faith in how retail should work. Within a couple of days I was stood marvelling at my new purchase, more on which I’ll write later. But before that, I have to tell you the ‘good retail’ story! Being a curious sort of soul, I opened the spare canister and compared it to the canister fitted in the vest …. there was a difference. The electrical connector in the vest was a locking two-pin item, but on the spare canister it was a jack plug. Hmm … had I ordered the wrong one? Back to sportsbikeshop …. no, they only listed the one type of 100g canister. OK, over to the Helite website and slap me sideways, only the same canister with the jack plug is shown. Now I

Within a couple of days I was stood marvelling at my new purchase, more on which I’ll write later. But before that, I have to tell you the ‘good retail’ story! Being a curious sort of soul, I opened the spare canister and compared it to the canister fitted in the vest …. there was a difference. The electrical connector in the vest was a locking two-pin item, but on the spare canister it was a jack plug. Hmm … had I ordered the wrong one? Back to sportsbikeshop …. no, they only listed the one type of 100g canister. OK, over to the Helite website and slap me sideways, only the same canister with the jack plug is shown. Now I  was stumped. So the next day I called Helite and received a massive apology as it turned out the new vests (Mk2?) have the locking plug connector and a batch of spare canisters had only just been received, so no distributors had them yet! Now this could turn ugly … Helite could say get your distributor to sort it out and the distributor could argue they sold me what Helite say fits. But not in this case – both were fantastic, Helite sent Sportsbikeshop a batch of canisters and explained the issue, meanwhile Sportsbikeshop and I swapped a couple of emails and hey-presto a correct canister arrived this morning, just 48hrs after noticing the problem … no fuss, no arguing, just good old fashioned customer support – so thank you both, I’ll be buying from you again that’s for sure!

was stumped. So the next day I called Helite and received a massive apology as it turned out the new vests (Mk2?) have the locking plug connector and a batch of spare canisters had only just been received, so no distributors had them yet! Now this could turn ugly … Helite could say get your distributor to sort it out and the distributor could argue they sold me what Helite say fits. But not in this case – both were fantastic, Helite sent Sportsbikeshop a batch of canisters and explained the issue, meanwhile Sportsbikeshop and I swapped a couple of emails and hey-presto a correct canister arrived this morning, just 48hrs after noticing the problem … no fuss, no arguing, just good old fashioned customer support – so thank you both, I’ll be buying from you again that’s for sure! During its life the Capo has had two Lithium batteries – the original Shorai, fitted in October 2011 and used for about 3 months, and now the

During its life the Capo has had two Lithium batteries – the original Shorai, fitted in October 2011 and used for about 3 months, and now the

Today I mourn the passing of my soulmate, best friend and wife of almost 30 years – Janet. She fought so bravely for two years against cancer, but was finally taken from us yesterday after a sudden and unexpected downturn. Family were at her side at the end as she passed peacefully. Today the pillion seat is empty and the intercom silent …. for over thirty years we travelled together on two wheels. Goodnight my beloved sweetheart.

Today I mourn the passing of my soulmate, best friend and wife of almost 30 years – Janet. She fought so bravely for two years against cancer, but was finally taken from us yesterday after a sudden and unexpected downturn. Family were at her side at the end as she passed peacefully. Today the pillion seat is empty and the intercom silent …. for over thirty years we travelled together on two wheels. Goodnight my beloved sweetheart.

Secondly, I bit the bullet on an

Secondly, I bit the bullet on an

And so the moment came and went without fanfare after a year of lockdown, no trips back and forth to home in Italy, no big holiday rides here in the UK. A year where mileage clocked up painfully slowly, the Capo sitting idle way more than doing what it does best – eat miles and promote smiles!

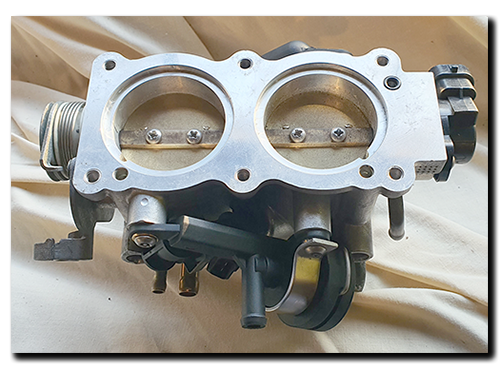

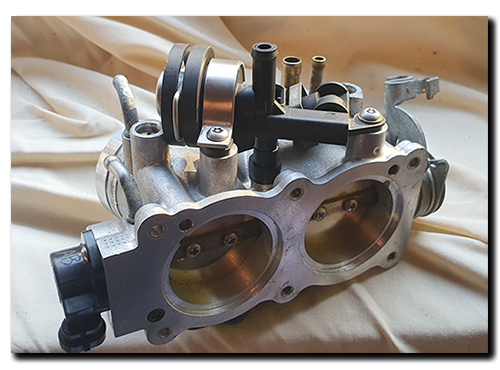

And so the moment came and went without fanfare after a year of lockdown, no trips back and forth to home in Italy, no big holiday rides here in the UK. A year where mileage clocked up painfully slowly, the Capo sitting idle way more than doing what it does best – eat miles and promote smiles! Sometime way-back-when, I bought a used set of throttle bodies off an RTS Futura (51mm v Caponord 47mm) with the view of doing some tuning/comparison work on the Raid with the 3D printed hybrid velocity stacks (51mm diameter but Caponord height). What really happened though was far less glamourous and only involved a sturdy box and a shelf! But about a month ago I dug them out again and realised that I pretty much had all the ingredients required to do a full clean and rebuild. I had stainless steel 4x10mm and 5x12mm Torx screws on the shelf as well as all necessary seals. The ultrasonic cleaning bath would do the brunt of the work and I could send the injectors away for professional cleaning at a reasonable cost.

Sometime way-back-when, I bought a used set of throttle bodies off an RTS Futura (51mm v Caponord 47mm) with the view of doing some tuning/comparison work on the Raid with the 3D printed hybrid velocity stacks (51mm diameter but Caponord height). What really happened though was far less glamourous and only involved a sturdy box and a shelf! But about a month ago I dug them out again and realised that I pretty much had all the ingredients required to do a full clean and rebuild. I had stainless steel 4x10mm and 5x12mm Torx screws on the shelf as well as all necessary seals. The ultrasonic cleaning bath would do the brunt of the work and I could send the injectors away for professional cleaning at a reasonable cost.

I really like fasteners, I hate rusty, corroded or damaged fasteners. There it is out in the open, plain and simple. I think there’s something tragic about lots of hard work going into an assembly, only for those old jaded screws/nuts/bolts/washers to go back into holding it together. On the other hand I’m not a fan of those OTT ‘custom fasteners’ – pike nuts etc or gaudy anodised fasters in any colour of the rainbow. For me, they are way overkill. What I want is an upgrade from the manufacturers items that were no doubt chosen with cost in mind. I like something that looks a little more up-market, in a material that is mechanically safe for the task in hand – safety has to override looks every time! They are there to do a job and complement the work that went into the parts they represent.

I really like fasteners, I hate rusty, corroded or damaged fasteners. There it is out in the open, plain and simple. I think there’s something tragic about lots of hard work going into an assembly, only for those old jaded screws/nuts/bolts/washers to go back into holding it together. On the other hand I’m not a fan of those OTT ‘custom fasteners’ – pike nuts etc or gaudy anodised fasters in any colour of the rainbow. For me, they are way overkill. What I want is an upgrade from the manufacturers items that were no doubt chosen with cost in mind. I like something that looks a little more up-market, in a material that is mechanically safe for the task in hand – safety has to override looks every time! They are there to do a job and complement the work that went into the parts they represent.

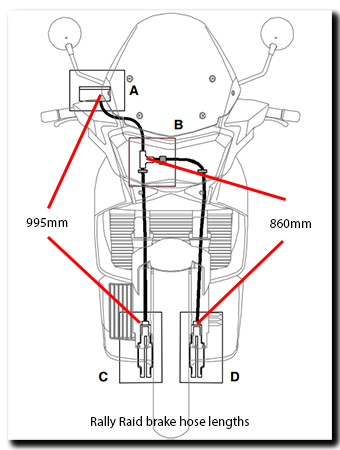

Well this little job just got a whole lot more involved and costly! The idea of having lovely clean and refreshed calipers made me think about the old banjo bolts (M10x1) and bleed screws (M8x1.25) … OK, so new stainless ones were ordered from

Well this little job just got a whole lot more involved and costly! The idea of having lovely clean and refreshed calipers made me think about the old banjo bolts (M10x1) and bleed screws (M8x1.25) … OK, so new stainless ones were ordered from  The standard hose assembly is a single hose from the reservoir to a T-piece just below the lower fork clamp, from there a single hose down to each caliper. To replicate this was actually more expensive than using two individual lines from the brake master cylinder. So that’s what I went with –

The standard hose assembly is a single hose from the reservoir to a T-piece just below the lower fork clamp, from there a single hose down to each caliper. To replicate this was actually more expensive than using two individual lines from the brake master cylinder. So that’s what I went with –