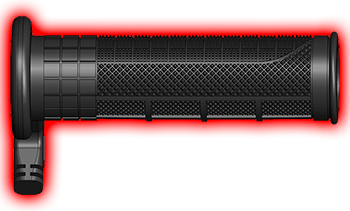

After a couple of rides, here’s the verdict on the Oxford Adventure heated grips – utterly Fantastic! Not only are they awesome in their toastiness, they really do help my old wrist as well. The extra diameter and better texture compared to the Ariete grips is lovely!

After a couple of rides, here’s the verdict on the Oxford Adventure heated grips – utterly Fantastic! Not only are they awesome in their toastiness, they really do help my old wrist as well. The extra diameter and better texture compared to the Ariete grips is lovely!

One thing lacking in my riding over the last few months has been blip-ability, the quick tweek of the wrist to grab a few revs … almost every downshift became a novice-style, crunchy-clunky affair, blips either non-existent or late. The head was doing the throttle blippy thing but the wonky wrist just couldn’t or wouldn’t play ball. Fair to say my blip-mojo was lost in sore tendons and swollen joints.

Now with fatter grips I’m chuffed to say my blip-mojo is back with a vengeance, sharp, snappy downshifts complemented with slick as Slick-50 on Teflon clutchless up-shifts as we slice through bend after hairpin bend. If the grin got any wider I’m sure the top of head would have fallen right off. At last, me and the gearbox are best mates again!

But that’s only half of it – These things work superbly as HEATED grips as well! With the days now struggling to reach 10-12C and wearing summer gloves, it takes but a couple of minutes at 100%, then swiftly backing the heat down to 40% before my fingers catch fire! That’s way better than the Aprilia grips ever performed. I do wonder if a big part of the Aprilia grips poor performance was not only down to the high-resistance heaters, but also the feeble wiring to the grips. I swear that stuff is rated to little more than 5 Amps, maybe 8 Amps on a good day with the wind behind it! Either way, they’re history now after a sterling 9 years service and I’m looking forward to seeing how well the Oxford grips last. Bring on a January ride through Switzerland ……. 😯

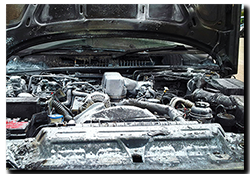

I figured it would be a good time to take the Capo off the road and replace the heated grips when it next rained …… and oh boy is it raining! 48Hrs now and another 24 to go if the met folk are to be believed. Plenty of time then to get the deed done, with a hot brew and cold beer somewhere along the way.

I figured it would be a good time to take the Capo off the road and replace the heated grips when it next rained …… and oh boy is it raining! 48Hrs now and another 24 to go if the met folk are to be believed. Plenty of time then to get the deed done, with a hot brew and cold beer somewhere along the way.

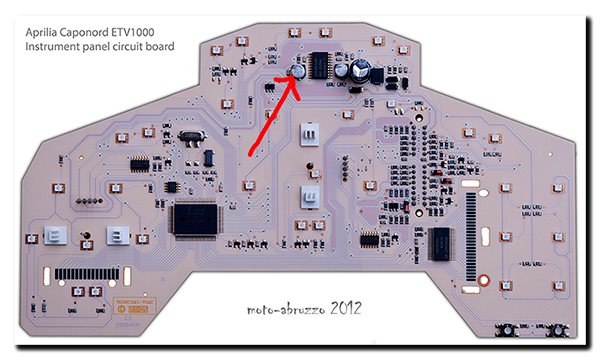

Yes, today I’m dishing the dirt on the number one bad-boy component on the Caponord and Futura dashboard. Or more to the point, why this sad little part earns this unwanted reputation! What is it? Well it’s a rather innocuous SMD radial electrolytic capacitor rated at 16V 47µF.

Yes, today I’m dishing the dirt on the number one bad-boy component on the Caponord and Futura dashboard. Or more to the point, why this sad little part earns this unwanted reputation! What is it? Well it’s a rather innocuous SMD radial electrolytic capacitor rated at 16V 47µF.

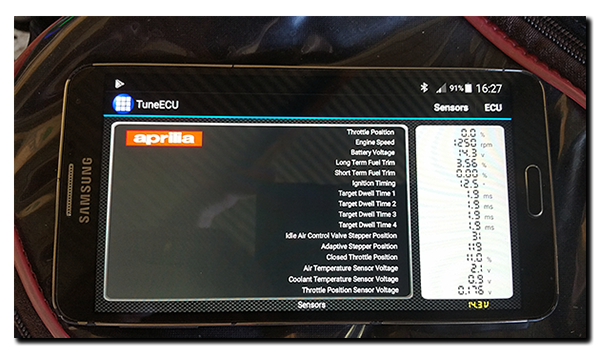

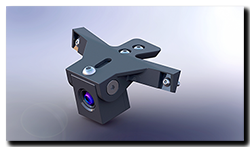

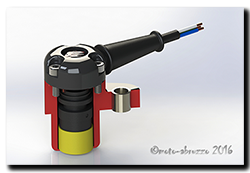

Hot on the heels of the last post, here we go again, with the next little problem to work on. It looks like the bad wrist isn’t going to recover much more now without an operation, and Dog knows when that’ll happen. So I’ve been pondering how to reduce the load (torque) my poor old wrist feels at the twist grip.

Hot on the heels of the last post, here we go again, with the next little problem to work on. It looks like the bad wrist isn’t going to recover much more now without an operation, and Dog knows when that’ll happen. So I’ve been pondering how to reduce the load (torque) my poor old wrist feels at the twist grip. to your last used setting ….. but none of this is programmed in on the OF690.

to your last used setting ….. but none of this is programmed in on the OF690.