With plans a-foot to assemble a big-cc motor for the Capo, it was time to cast an inquisitive eye over the airbox snorkel, that ugly rubber protrusion at the front of the airbox, sucking in hot air from on top of the radiator. This one object has been debated far and wide over the years – keep it, or remove it? Yes the questionable snorkelectomy!

With plans a-foot to assemble a big-cc motor for the Capo, it was time to cast an inquisitive eye over the airbox snorkel, that ugly rubber protrusion at the front of the airbox, sucking in hot air from on top of the radiator. This one object has been debated far and wide over the years – keep it, or remove it? Yes the questionable snorkelectomy!

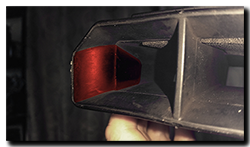

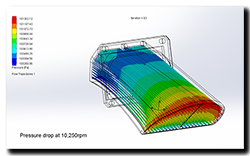

Only a couple of ways to find out I guess. Dyno the bike with and without it or draw it up and run a flow analysis on it from the comfort of an armchair. Armchair it is then! With the model  complete, here’s a couple of basic facts: Snorkel Inlet area (total) 1,750mm² and outlet area (total) 3,050mm². So the inlet is slightly restricted, the offending area is highlighted in the picture (click to enlarge). In fact, if the restriction were removed, the snorkel would have an inlet nearer to 2,400mm² – about 37% more!

complete, here’s a couple of basic facts: Snorkel Inlet area (total) 1,750mm² and outlet area (total) 3,050mm². So the inlet is slightly restricted, the offending area is highlighted in the picture (click to enlarge). In fact, if the restriction were removed, the snorkel would have an inlet nearer to 2,400mm² – about 37% more!

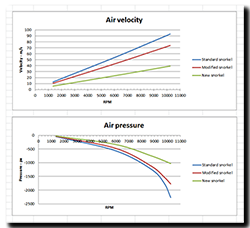

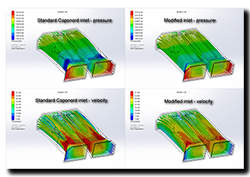

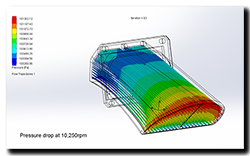

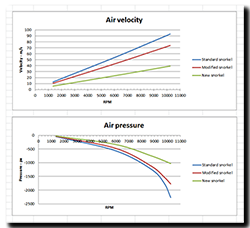

To keep it simple the analysis was run with air at 1013mb and 20C, both with AND without the  restriction in place and at RPM’s ranging from 1,300 to 10,250 – well above Caponord max RPM of 8,750.

restriction in place and at RPM’s ranging from 1,300 to 10,250 – well above Caponord max RPM of 8,750.

I think it’s reasonable to say that the OEM snorkel doesn’t really do badly until it hits 9,000RPM+ and lets face it, by then the whole thing is over for the poor old Capo anyway! Based on a days digital twiddling and some airbox datalogging several years ago, I have to say that I’m planting my flag firmly in the ‘leave it alone’ camp when it comes to the OEM Capo snorkel. It isn’t and never will be an RSV so why try to make it like one ….. the standard bits are designed to work well enough together for the style of bike it is. Yes of course remapping will improve things no end, but why screw up the ride by making it noisier and offering the local mice a HUGE entrance through which to set up an epic knocking shop on  the air filter!

the air filter!

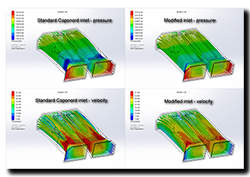

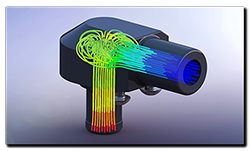

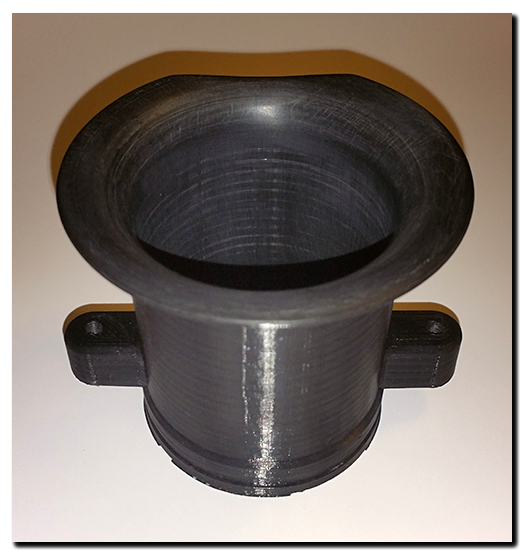

But what about the big-cc conversion? well running the analysis with the 1,103cc and 1,127cc flow certainly seemed to cast doubt on the suitability of the OEM snorkel as the strong pressure drop is now occurring lower down the rev range. So the snorkel design originally drawn up back in October 2012 was dug out of hibernation, modified and polished up for 3D printing and run through the flow software – the green line on the graph above. Overall it seems to offer a cleaner flow, less pressure drop and maintains a similar airflow velocity into the airbox. Unfortunately the one thing the software can’t tell me is how much extra  noise will be generated! The OEM snorkel is made of PVCD (flexible) AND has a foam pad in the roof of each inlet – both presumably are to reduce inlet noise.

noise will be generated! The OEM snorkel is made of PVCD (flexible) AND has a foam pad in the roof of each inlet – both presumably are to reduce inlet noise.

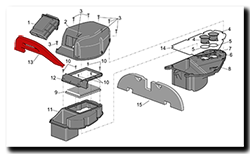

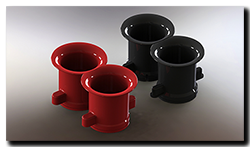

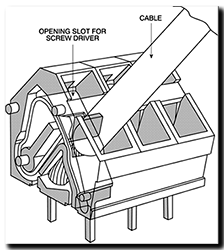

With everything looking OK a few test parts were printed to make sure it’s going to fit, then the model was split into two along the mounting plate and both parts printed separately. This was due both to size limitations in the printer and because I didn’t want to use any support material to upset the surface finish. Afterwards both parts were bonded together and the inlet tracts rubbed down with 80/180/400/1200 grit sandpaper to get a reasonable finish.

With a bead of sealant and 4x M4x12 and 4x M5x12 screws and nyloc-nuts, the snorkel fits into place just fine. Of course only time will tell how well it stands up to the rigours of its new home! The OEM snorkel has a rubber/foam acoustic panel (AP8117151) that fits over it and of course it won’t fit the new one, so I’ve trimmed this one to suit(ish) and placed an order for a similar dual-material sound deadening product to make a new one specifically for this snorkel. However the chopped-about old panel can’t be far off the ball park, as inlet noise just wasn’t noticeable which was a pleasant surprise …… It could well be a different story from the saddle though! 🙄

With a bead of sealant and 4x M4x12 and 4x M5x12 screws and nyloc-nuts, the snorkel fits into place just fine. Of course only time will tell how well it stands up to the rigours of its new home! The OEM snorkel has a rubber/foam acoustic panel (AP8117151) that fits over it and of course it won’t fit the new one, so I’ve trimmed this one to suit(ish) and placed an order for a similar dual-material sound deadening product to make a new one specifically for this snorkel. However the chopped-about old panel can’t be far off the ball park, as inlet noise just wasn’t noticeable which was a pleasant surprise …… It could well be a different story from the saddle though! 🙄

So what next? Well the plan is to get a day on a dyno when the weather is more amenable. I’d like to run it as standard, standard + new snorkel and Futura throttle bodies, new velocity stacks and new snorkel and see what the numbers say. Any guesses?

After January’s awful weather – snow, rain, sub-zero temps, earthquakes & landslides, it’s been a very nice balmy February! So much so, that the Capo has squirreled a good few miles under its belt – the last 300 of them with the new snorkel in place. And I have to say, I’m really chuffed at how it performs. No extra induction noise that my aged arthritic lug holes can detect and no detriment to performance even though it’s been nowhere near a dyno to tweak the mapping.

After January’s awful weather – snow, rain, sub-zero temps, earthquakes & landslides, it’s been a very nice balmy February! So much so, that the Capo has squirreled a good few miles under its belt – the last 300 of them with the new snorkel in place. And I have to say, I’m really chuffed at how it performs. No extra induction noise that my aged arthritic lug holes can detect and no detriment to performance even though it’s been nowhere near a dyno to tweak the mapping. As I write, a swanky set of Futura throttle bodies are winging their way here, as are a nice new pair of Mk2 cam chain tensioners – AP0236253. The velocity stacks are now finished and ready to fit to the throttle bodies and so it just leaves the matter of swapping out the Anakee Wild tyres for a fresh set of Anakee 3’s and a DID ZVM-X chain and Ognibene front/rear sprocket set (courtesy of Motrag) and I think she’ll be ready for a damn good thrashing on Dr Dyno! 🙂

As I write, a swanky set of Futura throttle bodies are winging their way here, as are a nice new pair of Mk2 cam chain tensioners – AP0236253. The velocity stacks are now finished and ready to fit to the throttle bodies and so it just leaves the matter of swapping out the Anakee Wild tyres for a fresh set of Anakee 3’s and a DID ZVM-X chain and Ognibene front/rear sprocket set (courtesy of Motrag) and I think she’ll be ready for a damn good thrashing on Dr Dyno! 🙂

With plans a-foot to assemble a big-cc motor for the Capo, it was time to cast an inquisitive eye over the airbox snorkel, that ugly rubber protrusion at the front of the airbox, sucking in hot air from on top of the radiator. This one object has been debated far and wide over the years – keep it, or remove it? Yes the questionable snorkelectomy!

With plans a-foot to assemble a big-cc motor for the Capo, it was time to cast an inquisitive eye over the airbox snorkel, that ugly rubber protrusion at the front of the airbox, sucking in hot air from on top of the radiator. This one object has been debated far and wide over the years – keep it, or remove it? Yes the questionable snorkelectomy!

With a bead of sealant and 4x M4x12 and 4x M5x12 screws and nyloc-nuts, the snorkel fits into place just fine. Of course only time will tell how well it stands up to the rigours of its new home! The OEM snorkel has a rubber/foam acoustic panel (AP8117151) that fits over it and of course it won’t fit the new one, so I’ve trimmed this one to suit(ish) and placed an order for a similar dual-material sound deadening product to make a new one specifically for this snorkel. However the chopped-about old panel can’t be far off the ball park, as inlet noise just wasn’t noticeable which was a pleasant surprise …… It could well be a different story from the saddle though! 🙄

With a bead of sealant and 4x M4x12 and 4x M5x12 screws and nyloc-nuts, the snorkel fits into place just fine. Of course only time will tell how well it stands up to the rigours of its new home! The OEM snorkel has a rubber/foam acoustic panel (AP8117151) that fits over it and of course it won’t fit the new one, so I’ve trimmed this one to suit(ish) and placed an order for a similar dual-material sound deadening product to make a new one specifically for this snorkel. However the chopped-about old panel can’t be far off the ball park, as inlet noise just wasn’t noticeable which was a pleasant surprise …… It could well be a different story from the saddle though! 🙄

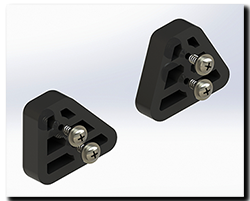

another one, when I had a “Stop the bus!” moment …… don’t waste time and fuel going into town, sit down, draw something in CAD and print that puppy! 😀

another one, when I had a “Stop the bus!” moment …… don’t waste time and fuel going into town, sit down, draw something in CAD and print that puppy! 😀

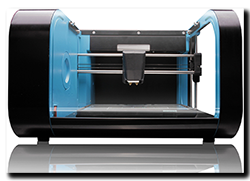

Yesterday, on a rather cold and wet afternoon, moto-abruzzo took a step into the future ……. courtesy of a good friend that I’m doing a project for. A 3D printer arrived! And being the top man that he is, he’s cool about me printing off those odd little Caponord bits-n-bobs.

Yesterday, on a rather cold and wet afternoon, moto-abruzzo took a step into the future ……. courtesy of a good friend that I’m doing a project for. A 3D printer arrived! And being the top man that he is, he’s cool about me printing off those odd little Caponord bits-n-bobs.

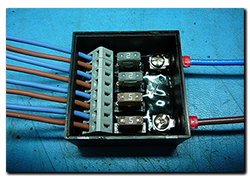

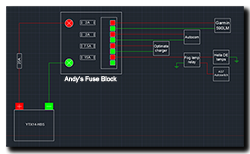

Unfortunately, due to circumstances I won’t elaborate on just yet, I found myself with a bunch of cut accessory cables sorely in need of a home! So step forward front-and-centre the fuse block made by Beasthonda (Andy) from the

Unfortunately, due to circumstances I won’t elaborate on just yet, I found myself with a bunch of cut accessory cables sorely in need of a home! So step forward front-and-centre the fuse block made by Beasthonda (Andy) from the

And that’s it …… one neat block and no more external fuses.

And that’s it …… one neat block and no more external fuses.  I had a bit of a stress-monster moment last night. After finishing off a bit of work on the Capo, I fired it up and stuffed the multimeter probes across the battery terminals –

I had a bit of a stress-monster moment last night. After finishing off a bit of work on the Capo, I fired it up and stuffed the multimeter probes across the battery terminals –