The new vacuum check-valve (AP8104251) arrived yesterday and today, while the rain poured endlessly from a depressingly black sky I set about swapping out the bad one on the front cylinder. Just to be Boy-Scout ready, I’d also made sure to have some new hose and stainless steel click-clamps to hand – just in case! Getting the old one

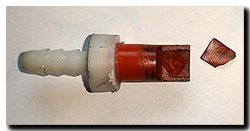

The new vacuum check-valve (AP8104251) arrived yesterday and today, while the rain poured endlessly from a depressingly black sky I set about swapping out the bad one on the front cylinder. Just to be Boy-Scout ready, I’d also made sure to have some new hose and stainless steel click-clamps to hand – just in case! Getting the old one  out is a real trial of patience and dexterity believe me! Here is a pic of the old valve cut in half and you can see that the valve has broken up completely.

out is a real trial of patience and dexterity believe me! Here is a pic of the old valve cut in half and you can see that the valve has broken up completely.

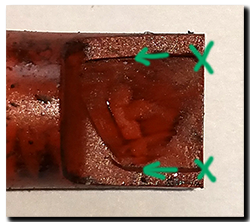

With the valve cycling anywhere between an estimated 11-73 times a second depending on RPM, it looks like the 0.5mm thick valve flaps suffer from fatigue and rips develop where the material flexes most. The valve doesn’t completely fail until the flap is ripped away as my other (rear cylinder) valve is testimony too. That valve flows in one direction but also a very small amount in the other and when  viewed end on, light can be seen through the valve flaps leading me to think that rips have already begun. So now another new valve is on order and I guess I’ll make a note to check these again in 15K miles or so, it’s easy and quick to do – simply pucker up and suck or blow! 😳

viewed end on, light can be seen through the valve flaps leading me to think that rips have already begun. So now another new valve is on order and I guess I’ll make a note to check these again in 15K miles or so, it’s easy and quick to do – simply pucker up and suck or blow! 😳

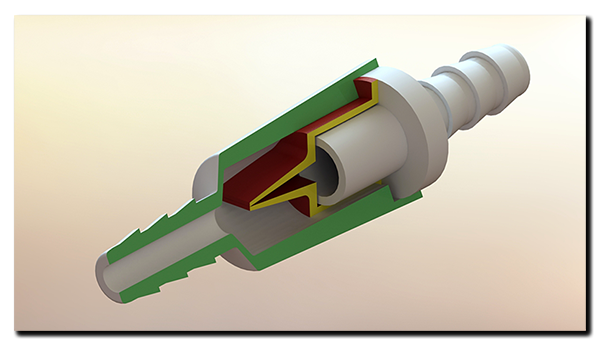

Oh and I’ve been asked a couple of times …. why not use a cheap Ebay ball-valve replacement? Well it seems to me they’re just not designed to cycle rapidly, a ball/spring valve may well be susceptible to the same phenomena as an engine valve train at high rpm – valve bounce/float. Of course in the real world it may make no damn difference what so ever and I’m just a sucker for buying genuine Aprilia parts! 🙂

Oh and I’ve been asked a couple of times …. why not use a cheap Ebay ball-valve replacement? Well it seems to me they’re just not designed to cycle rapidly, a ball/spring valve may well be susceptible to the same phenomena as an engine valve train at high rpm – valve bounce/float. Of course in the real world it may make no damn difference what so ever and I’m just a sucker for buying genuine Aprilia parts! 🙂

UPDATE

Second (rear cylinder) valve replaced and all now in perfect condition. In this case the valve was leaky as it had a tear down one side – so a partial rather than total failure. It also seems that these parts were upgraded some time ago, this looks like it’s a modification to the plastic body …. on the old one the case is simply presses together, on the new one it is welded. Maybe they had instances of the cases coming apart in service, who knows.

Second (rear cylinder) valve replaced and all now in perfect condition. In this case the valve was leaky as it had a tear down one side – so a partial rather than total failure. It also seems that these parts were upgraded some time ago, this looks like it’s a modification to the plastic body …. on the old one the case is simply presses together, on the new one it is welded. Maybe they had instances of the cases coming apart in service, who knows.